We use cookies to provide the best site experience.

Ok, don't show again

Data-driven operational efficiency

Use equipment telemetry and state-of-the-art predictive deep learning models to reduce waste, equipment failures and increase raw material utilization

Increase yeild and decrease costs by forecasting quality deterioration, catalyst depletion, failures, downtimes and overall process degradation.

Chemicals

Chemicals Oil and gas

Oil and gas Metals and mining

Metals and mining Pulp and paper

Pulp and paper

datarythmics effimly

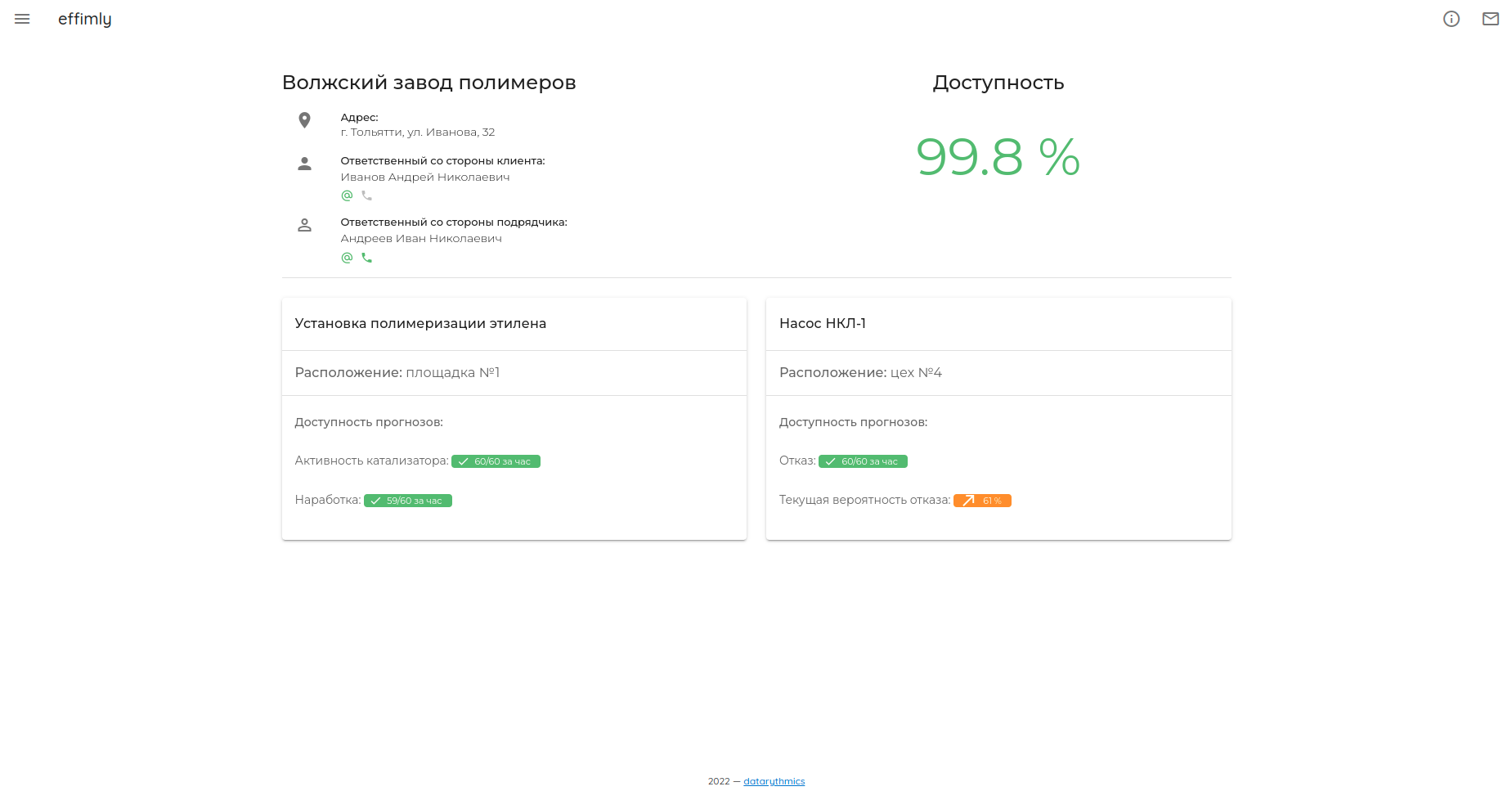

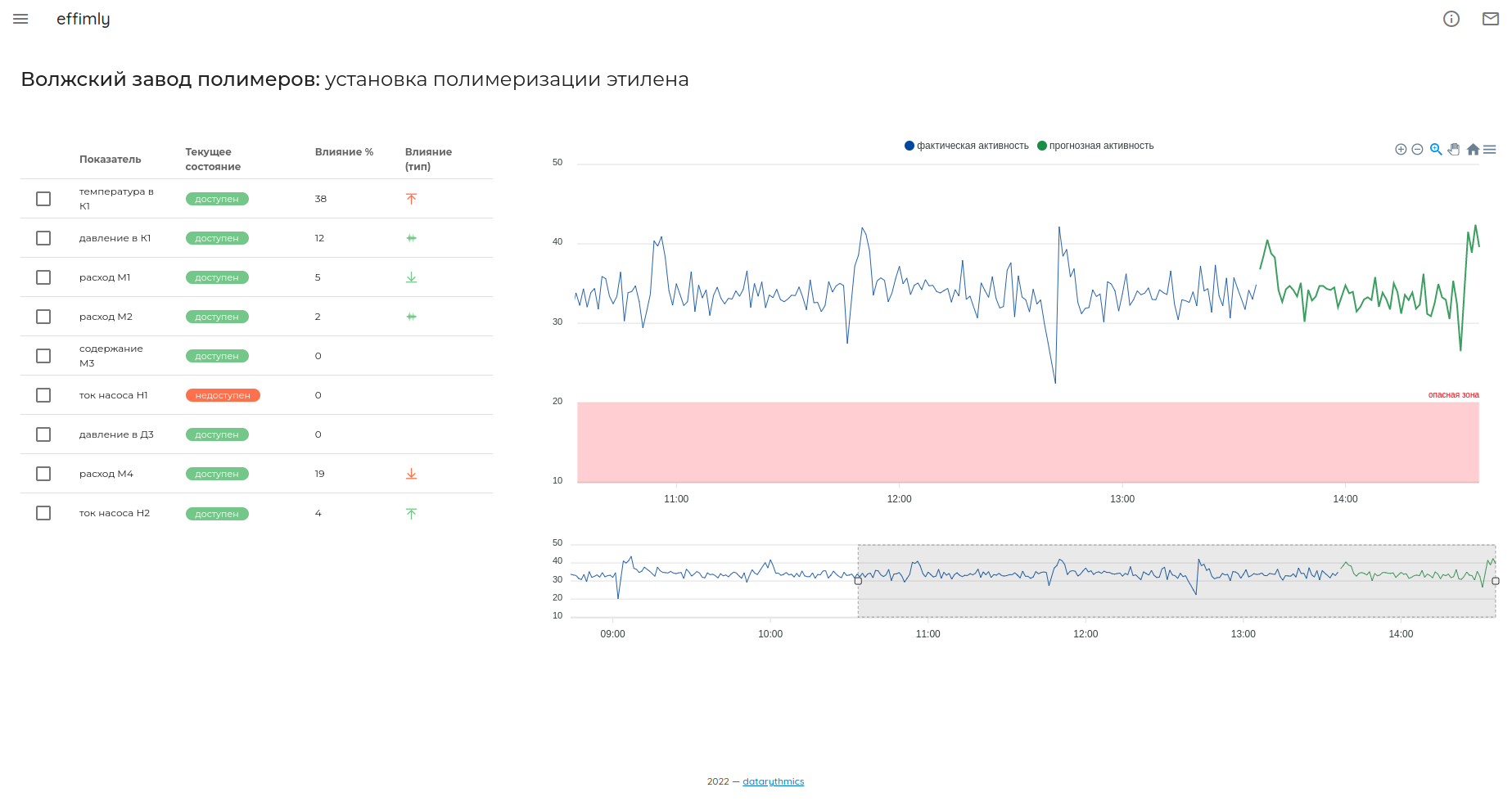

Cloud system for process manufacturing forecasting

- Model libraryExtensive deep learning models library for fast roll-out. You only need to provide historical data, and we'll train the best possible model for the task.

- Interpretabilityeffimly estimates input factors impact, both quantitatively (how much each factors impact the forecast) and qualitatively (value is too high, too low, too volatile, and more).

- Fast deploymentOnline data transfer is secure and easy to setup with effimly SDK. We'll do the rest, including API and dashboard.

- SubscriptionWhen the system is ready, you only pay for what is really used. Subscription fee scales with number of input data streams used and data frequency.

Tilda Publishing

Custom services we provide

- Root cause analysisData-drivenWe analyze historical telemetry to uncover main sources of equipment failures or inefficiencies and provide actionable insights to improve equipment performance.

- GISSatellite, aerial, LIDARWe analyze and build data products out of vector, raster (satellite and aerial imagery) and point cloud (LIDAR) GIS data to bring operational efficiency into mining and forestry industries.

- Consulting and trainingOnline or onsiteWe provide training and consulting services on how to start and manage data-driven projects and improve institutional readiness to machine learning adoption.

Together with AI Today.

Request a call

Request a call

Request a call

Request a demo

You agree to our Terms and Conditions